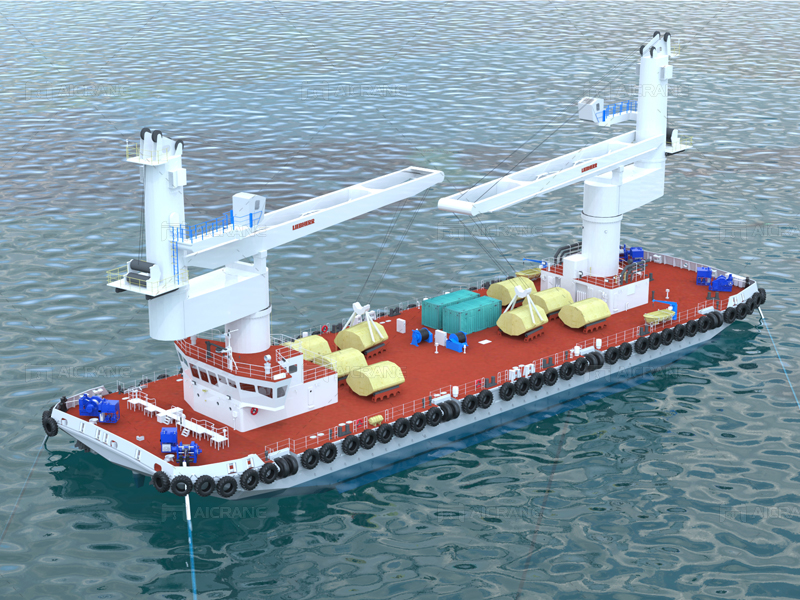

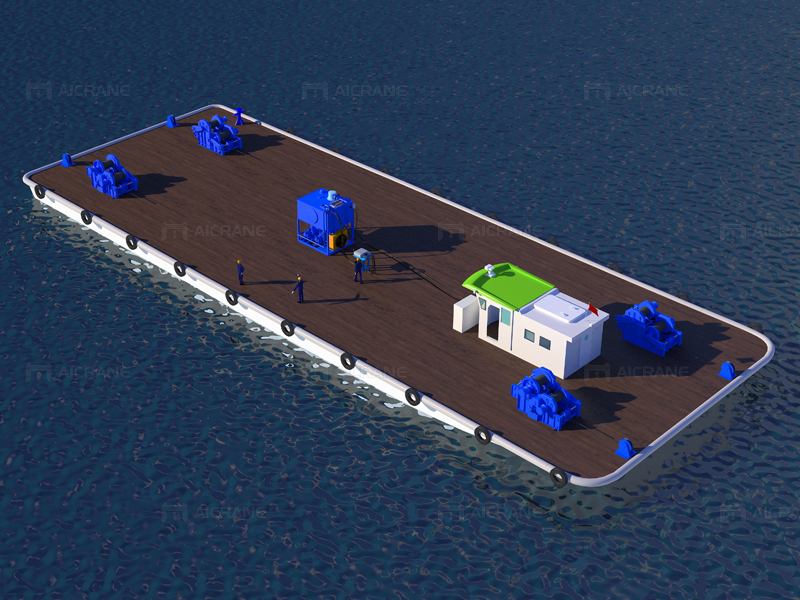

Offshore winch operations play a crucial role in various industries, including oil and gas exploration, marine construction, and renewable energy projects. These specialized winches are designed to handle heavy loads in harsh offshore environments, but they also face unique challenges that demand careful consideration and innovative solutions. In this article, we will explore some of the main challenges encountered in offshore winch operations.

1. Harsh Environmental Conditions:

One of the primary challenges in offshore winch operations is the exposure to harsh environmental conditions. Offshore sites often experience high winds, rough seas, and extreme temperatures, making it imperative for winches to withstand these elements. Corrosion, a common issue in saltwater environments, can impact the structural integrity of the components of the winch offshore. Engineers and manufacturers must employ advanced materials and coatings to enhance the winch’s resistance to corrosion and ensure longevity.

2. Deep-Sea Challenges:

In offshore activities, winches are frequently deployed in deep-sea applications where water depths can exceed thousands of meters. Operating under extreme pressure and in total darkness poses significant challenges. Ensuring the reliability and functionality of winches at such depths demand meticulous engineering. Hydraulic systems and seals must be designed to withstand the pressure changes associated with varying depths, and electronic components must be adequately sealed to prevent water ingress.

3. Heavy Load Handling:

Offshore winches are designed to handle heavy loads, often in the range of several tons or more. The challenge lies in maintaining precise control and stability during lifting and lowering operations. The risk of dynamic loading, where sudden changes in load occur, can lead to equipment stress and failure. To address this challenge, advanced control systems and load monitoring technologies are implemented to provide real-time feedback and ensure safe and efficient operations.

4. Dynamic Positioning:

Vessels involved in offshore operations are often equipped with dynamic positioning (DP) systems to maintain a steady position, especially in deep waters where traditional anchoring is impractical. Coordinating the movements of the vessel with winch operations adds complexity. Winches must be synchronized with the DP system to ensure precise load placement and avoid collisions or entanglements. This requires sophisticated automation and control systems, along with skilled operators capable of managing multiple variables simultaneously.

5. Safety Considerations:

Safety is paramount in offshore operations, and marine winch operations are no exception. The risk of accidents, such as rope snaps or equipment malfunctions, can have severe consequences. Adequate training for operators, routine maintenance, and stringent safety protocols are essential. Emergency response plans must be in place to address unforeseen challenges promptly. Incorporating fail-safe mechanisms and redundant systems can add an extra layer of protection.

6. Remote Location Logistics:

Offshore platforms and installations are often located in remote areas, far from supply hubs and maintenance facilities. This presents logistical challenges in terms of sourcing spare parts, conducting regular maintenance, and addressing unexpected breakdowns. Establishing efficient supply chains and maintenance schedules is crucial to minimizing downtime and ensuring the continuous operation of offshore winches.

7. Corrosion Management:

Corrosion is an ever-present threat in offshore environments due to the corrosive nature of saltwater. Regular inspections and preventive maintenance are vital to managing corrosion and preventing equipment degradation. Utilizing corrosion-resistant materials, protective coatings, and cathodic protection systems can mitigate the impact of corrosion, but ongoing vigilance is necessary.

8. Integration with Existing Infrastructure:

In some cases, offshore winches need to be integrated into existing offshore infrastructure, such as oil rigs or platforms. Ensuring seamless integration without disrupting ongoing operations requires careful planning and engineering expertise. Compatibility with existing control systems, power sources, and structural considerations must be taken into account to facilitate a smooth transition.

9. Energy Efficiency:

Offshore operations demand significant energy inputs, and optimizing energy efficiency is a growing concern. Winches that operate on vessels or platforms need to balance power requirements with sustainable energy practices. Integrating energy recovery systems, such as regenerative braking, can contribute to reducing the overall energy consumption of winch operations.

10. Regulatory Compliance:

Offshore operations are subject to stringent regulations to ensure environmental protection, worker safety, and overall industry compliance. Navigating the complex web of regulations poses a challenge for operators and requires continuous monitoring and adaptation. Offshore winch systems must be designed and operated in accordance with industry standards and regulatory requirements to obtain necessary certifications and approvals.

In conclusion, offshore winch operations present a myriad of challenges, from environmental extremes to complex logistics and safety considerations. The ongoing evolution of technology, materials, and operational practices is essential to overcoming these challenges and ensuring the success of offshore projects. As the demand for offshore resources and renewable energy continues to grow, addressing these challenges will be crucial for the sustainable and efficient operation of offshore winches in the years to come. For more info, click here https://winchmachines.com/